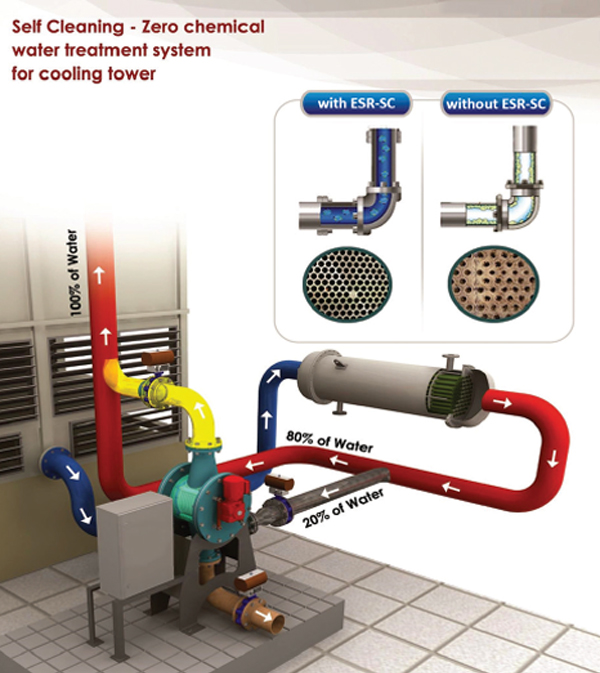

operation without adding chemicals (Zero Chemical).”

The following operational issues arise from these problems:

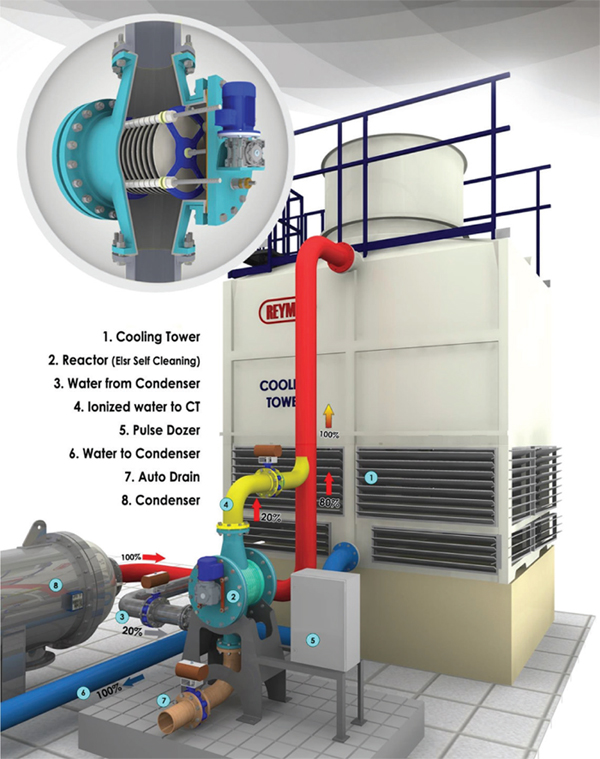

Electrolytic Scale Remover (ESR) system

Technical & Chemical Process

Technical Innovation

Potential Benefits of Electrolytic Scale Remover

Effect in Condenser

The photograph shows the conditions of heat exchanger tubes before and after installation of Electrostatic Scale Remover. Previously (left photo), scale had built-up so much that heat exchanger tubes were blocked, but after six months of installation and operation (right photo), the adhesion status has significantly improved.

Electrolytic Scale Remover (ESR-MC) is a Manual Cleaning system. In this system the scale is to be removed manually at regular intervals, when the cleaning indicator on the panel lights up.

Automatic Self-Cleaning Electrolytic Scale Remover (Esr-Sc)

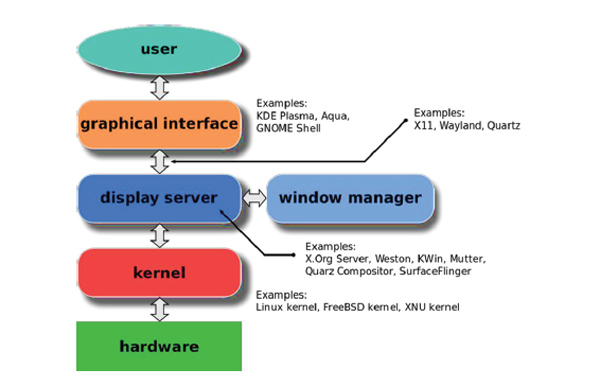

ESR-SC User Interfacing

User interface is part of software and is designed in such a way that it is expected to provide the user insight of the software to monitor and control the operation of ESR-SC system, below are the various stages of user interfacing.

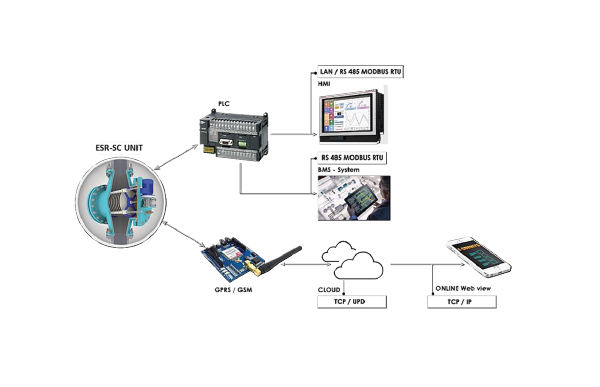

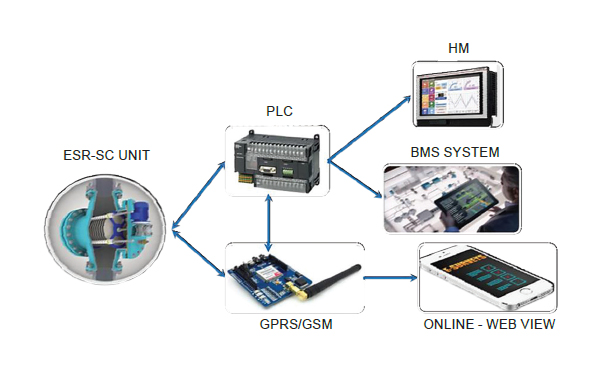

Protocol Topology

A protocol is a set of rules and guidelines for communicating data. Rules are defined for each step and process during communication between two or more devices.

Networks have to follow these rules to successfully transmit data.

This ESR-SC system made with bi-directional data communication with two different modes of data link as wired and wireless communication.

On the basic field data is acquisitioned through the I/O module of master controller ‘PLC’ and communication established from PLC to local HMI and BMS system through communication protocol.

ESR-SC monitoring system linked with the internet protocols through second channel which are helping to see the system performance on web view.

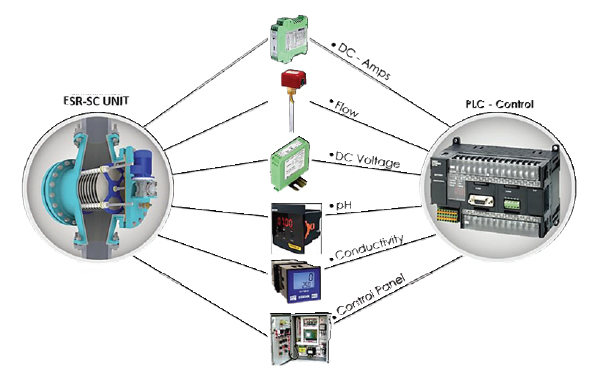

Data Acquisition

Data acquisition (DAQ) is the process of measuring an electrical or physical phenomenon such as voltage, current, temperature, pH, Conductivity, Flow, etc. This DAQ system consists of sensors, DAQ measurement hardware and I/O module which are linked with the PLC based local control system which will control the system operation and date log.

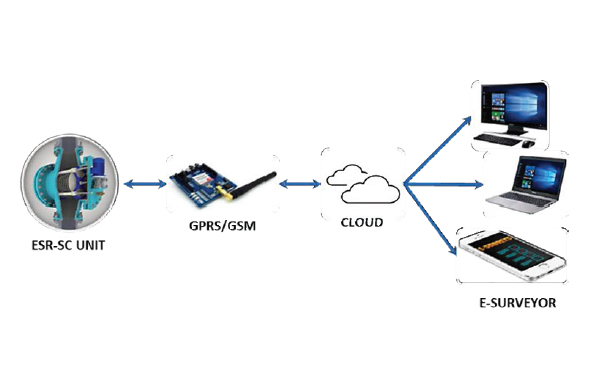

Cloud Computing

Cloud computing is shared pools of configurable computer system resources and higher-level services that can be rapidly provisioned with minimal management effort, often over the Internet. Cloud computing relies on sharing of resources to achieve coherence and ESR-SC operation data has collected by the local GPRS/ GSM modular device and same will loaded on cloud server, this SQL server is linked with secured web view application called ESURVEYOR.

Global Data Monitoring (E-Surveyor)

E-Surveyor is used to monitor process variables and predict final product quality at an early stage, while also providing the better understanding of the process. This allows engineers and production managers to optimize their processes, thereby realizing significant cost and time savings.

This write-up includes a background and explanation of some of the key points of E-Surveyor.

Highlights : The major part of E-Surveyor is to provide the set of analytical techniques and methods to ensure normal operating conditions. E-Surveyor technology can evaluate the process parameter and send the alert email if found any abnormality. Evaluation criteria includes criteria like ease of use, robustness, maintenance and cost.

Objectives : The aim of E-Surveyor is to dramatically upgrade the process management, ensuring a high level of safety and Preventive measures.

Data Flow : There are three stages of data flow which are data entry, data monitoring and data execution and control.

Communication

Communication protocols are formal descriptions of digital message formats and rules. They are required to exchange messages with or between computing systems. Communications protocols cover authentication, error detection, correction, and signaling. ESR-SC system initial communication is established from local control panel to field instruments through the signal cable which will be processed at central control unit PLC, logic controller is linked with local interfacing module (HMI) through Modbus TRU- RS 485.

ESR-SC system is facilitated with an addition Modbus TRU- RS 485 to communicate with user BMS system for local monitoring and a step ahead, our ESR-SC system is facilitated with Transmission Control/Internet protocols ‘TCP/IP’ for web viewing and global monitoring.

An online secured login application called E-Surveyor for user access and monitoring is provided with the system.

Remote Operation

ESR-SC system is facilitated with Remote ON/OFF through TCP/ IP protocol from web application and MODBUS RTU from BMS system.